When you are designing electronic subsystems for a new product or machine, you will encounter many make-or-buy decisions along the way. Those decisions are made based on several factors:

- Functional requirements

- Up-front engineering cost

- Per-unit cost

- Quantity needed

- Size / Form factor

- Timeline

- Security / Intellectual Property

Commercially Available Controls

The market is full of PLC and PAC products that are more powerful and less expensive than ever, with good development tools and a high degree of flexibility. For small quantities of custom machines, or machines that will be adjusted or modified by the end-user, this is generally a good option. It is easy to make changes later, as the systems are generally expandable and reconfigurable. The control software can be understood by people with electrical backgrounds, rather than being exclusive to software developers.

In this approach, you still need to perform the electrical engineering to design the circuits, mechanical engineering to design the mounting, and controls engineering to build the control logic. You avoid designing the control hardware itself, and you avoid custom manufacturing.

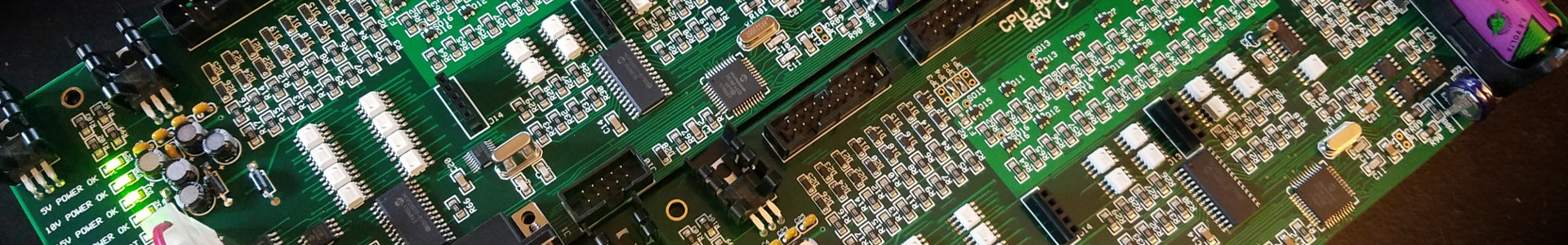

Custom Controls

When you are building larger quantities, or when the application is very cost-sensitive at even moderate quantities, or when the form factor is tightly constrained, custom microprocessor controls can be a viable option instead. Custom controls open up several possibilities that do not exist with off-the-shelf controls. You can build the needed functionality on a single component, rather than a collection of add-on modules, which can simplify purchasing, manufacturing, troubleshooting, maintenance, and spare parts stocking. You can fit the controls to whatever space is available, rather than including bulky control enclosures. You can build in any interfaces needed for unusual subsystems, such as non-standard electrical signalling, sensor amplification, diagnostic indication, or custom communication interfaces. You do not need to carry the overhead of all of the unneeded functionality that tends to be present in a general-purpose platform.

When designing custom controls, the application should be rigidly defined. If the functionality is expected to change over time, then the flexibility found in off-the-shelf controls could be a better choice. If the functionality is well defined though, you can design and build a control system that includes only the needed components and software, which will generally make for a smaller, simpler, and less expensive solution.

This option does add the cost of circuit and PCB design to the engineering effort, and an evaluation of that added cost against the per-unit savings is needed.

Other Custom Electronics

In addition to controls, custom electronics are often used where no commercially available option contains the required functionality. Some examples are:

- Specialized sensors

- Unusual communication interfaces

- Unique I/O needs or electrical interfaces

- Interfacing two incompatible devices

- Connections for ease of manufacturing / installation / maintenance

In these cases, you may find yourself in need of custom electronics, whether they are included on a custom controller or built as standalone interfaces to connect to an off-the-shelf PLC/PAC.

Basalogic Services

With your functional requirements, Basalogic can prepare estimates of both development and manufacturing costs, allowing you to make an informed decision as to whether custom or off-the-shelf electronics are a better fit for your device.

If custom electronics appear to be a viable choice, Basalogic can translate your functional requirements into schematics, PCB artwork, bills of material, and firmware. We can also produce your prototypes for functional testing, make any needed revisions, and proceed to full production. We can handle short-run production in-house, and larger runs with the help of our partners.